In the era of advanced technologies, aluminum structures have become a key innovative solution in modern construction. This material with unique characteristics and numerous advantages is indispensable and in demand for the construction of buildings and structures for various purposes.

Advantages of aluminum systems

Aluminum has become an integral part of a successful construction business due to its many benefits.

Lightness and strength

Technohome knows that aluminum is a fairly light metal, which at the same time has high strength. This advantage is very important in the construction of high-rise buildings, as reducing the weight of buildings reduces not only the cost of materials, but also simplifies logistics and reduces construction time.

Corrosion resistance

Corrosion has always been and remains one of the main threats to the longevity of buildings. Aluminum structures are highly resistant to corrosion, which increases their service life and reduces the need for regular maintenance.

This makes it possible to use aluminum systems for the construction of buildings in different climatic zones, as well as in places with constant and frequent changes in climatic conditions.

Environmental friendliness

Aluminum is an environmentally friendly material, which is particularly important in the U.S. construction industry, where high demands are placed on sustainability. In addition, aluminum is recyclable.

Energy efficiency and thermal conductivity

Aluminum’s ability to transfer heat efficiently makes it an excellent material for constructing energy-efficient buildings. Such structures can easily maintain an optimal indoor temperature, resulting in lower heating and air conditioning costs.

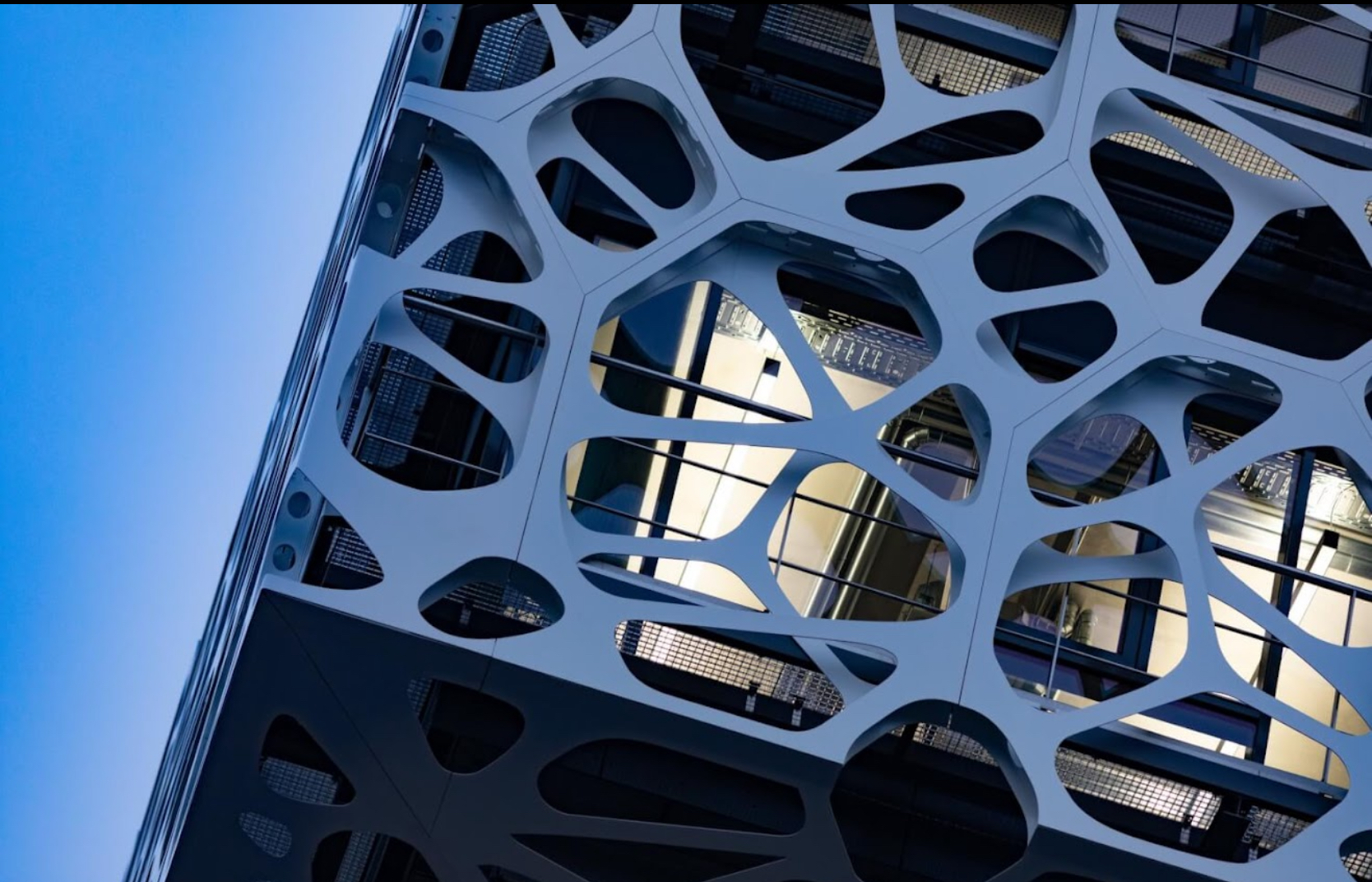

Architectural possibilities

Aluminum is not only a practical material. Its unique characteristics make it possible to create complex and non-standard architectural forms and realize even the most complex design ideas. Many construction companies use aluminum structures to create not only functional, but also attractive and aesthetic buildings.

The use of aluminum structures has become a strategic step in the modern construction business. The advantages of the material make it indispensable in the construction of innovative, environmentally friendly and visually appealing architectural projects.

Technohome aluminum systems – the key to success in the construction business

Our company today is one of the best in aluminum solutions for the US construction industry. With our own production of architectural aluminum systems, we do not sell our products independently but are the exclusive exporter of aluminum structures for building façade glazing, aluminum pergolas, reflexology, etc.

The main line of business is the B2B (“business to business”) segment. This is the creation of a dealer base in the USA and cooperation with large construction companies, developers and architects.

Our products, with an annual volume of 22,000 tons of all kinds of profiles, are supplied to Nevada, Massachusetts, California, New Jersey, New York, North and South Carolina, Arizona and many other US states, and exported to more than 40 countries around the world.

Today we are the world leader in the aluminum industry. Our company guarantees the best prices for all aluminum products, as well as good delivery times. It is made of environmentally friendly aluminum, and its high quality is confirmed by international certificates.

Production

Aluminum structures from Technohome are a combination of functionality, high quality, style and aesthetics. Production of aluminum systems is carried out on extrusion presses with different capacities – 1800, 2200 and 2800 tons.

The B2B market is characterized by high competition, so working in this segment, we have taken care to simplify the process of cooperation, making it as profitable as possible for customers.

In addition to the highest quality products, our company also provides a range of services and capabilities that include:

The range of services consists of design, technology development, testing, market analysis, and introduction of new products into mass production. This, as well as expert advice, ensures that all aluminum solutions fit seamlessly into any architectural idea.